LabGuy's World: Two Inch Format

VTR's

NEW! 02.05.07

NEW PHOTOS! 02.06.08

Ampex VR-660 Two Inch Half Helical VTR and a Memorex

tape!

This

is the elusive and rare Ampex VR-660(B?) with Edicon from 1963.

LabGuy's World has been seeking one of these for a very long time. The

first photo is provided by the fellow who sold me the machine. It took

three weeks to arrive, but now it is here for us all to enjoy! Overall,

the unit is in excellent condition considering how long it has been stored.

It did arrive with a couple of show stopper problems. The video heads had

been removed sometime in the past and the drum entry and exit guides are

not complete. I am working with the seller at this time to rectify these

problems. As usual, stay tuned for updates about that. If you have any

spare parts or service literature for this machine, be sure to contact

me!

Two Memorex tapes for the VR-660,

as seen in the second photo, were obtained recently from my newest friend,

Grant Newland. Thanks, Grant!

This machine can accommodate

a total of four different reel sizes containing differing amounts of tape

to give the appropriate running times. They were:

-

6. 5 inch reel, 750 feet of tape, 40 minutes.

-

8. 0 inch reel, 1650 feet of tape, 90 minutes / 1 hour & 30 minutes.

-

10. 5 inch reel, 3600 feet of tape, 195 minutes / 3 hours & 15 minutes.

-

12. 5 inch reel, 5540 feet of tape, 300 minutes / 5 hours. (That's over

1 mile of tape!)

Five hours recording time! Thirteen years

before VHS or long playing Betamax? Isn't that fascinating! And just imagine,

the entire film, Titanic, could fit on a single reel of tape! Again, a

dozen or more years before the long play DVD was invented! And you thought

TV was in a primitive state in the early 60s!

The "Edicon" is the fancy

name for the electronic editing controls built in this machine. In the

early 60s, this was a fantastic feature. From interviewing people who used

these VTRs, I have been told that they worked very well! In the next to

the last photo, you can see the Edicon control panel which allowed the

user ot select |

several different recording and editing modes.

Also visible is the transport control joystick. Sadly, the ID label is

seriously faded, but the word Edicon can be made out with the naked eye.

The last photo is of the jack bay.

Ampex produced another

model, the VR-1500, which is interchange compatible with the VR-660. The

VR-1500 was actually marketed, though not very enthusiastically, as a possible

consumer home VTR.

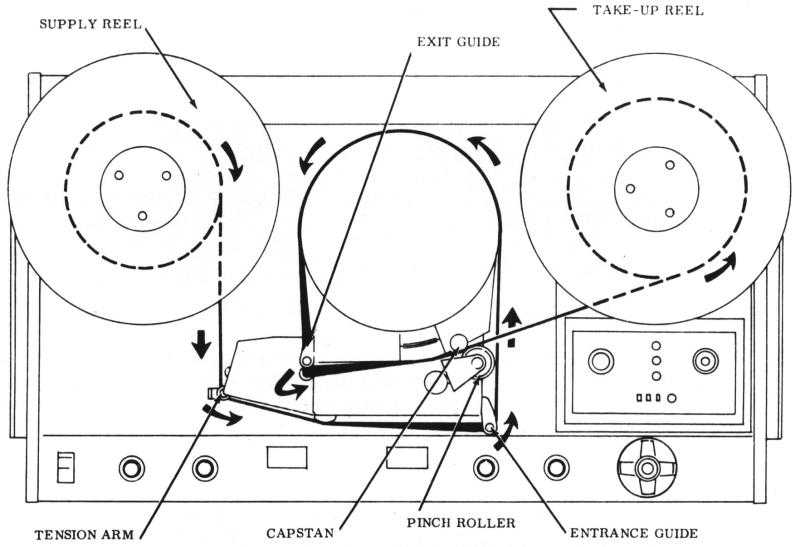

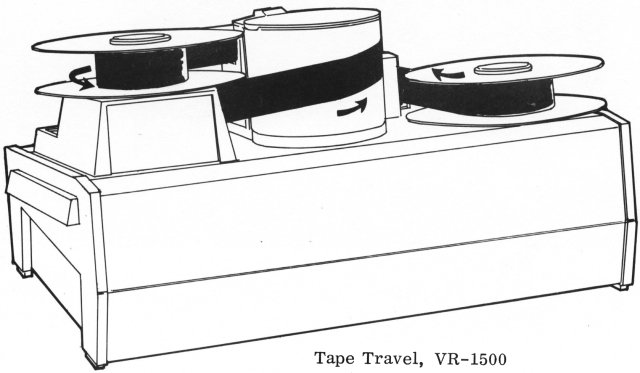

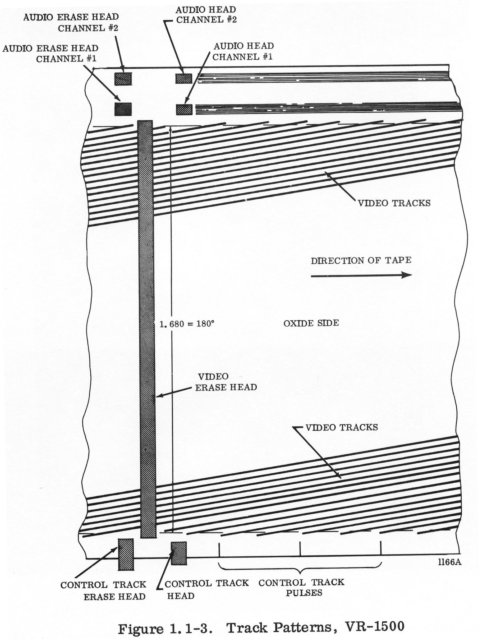

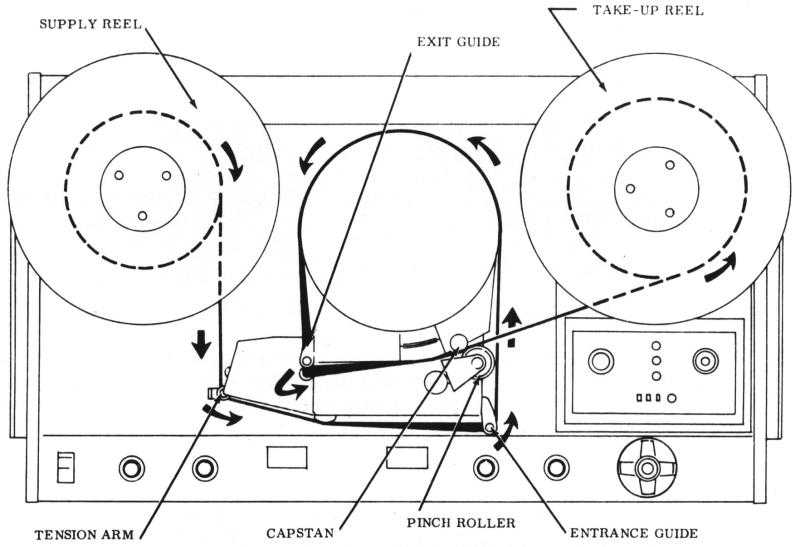

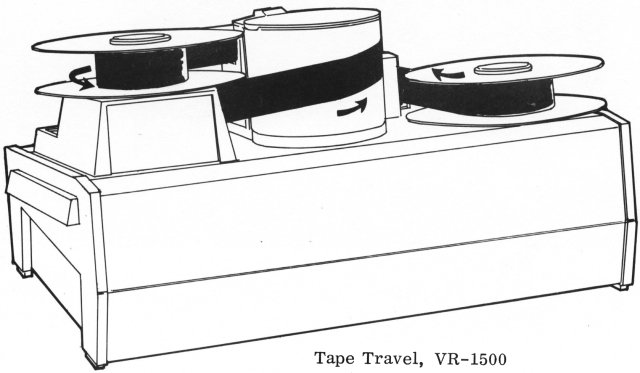

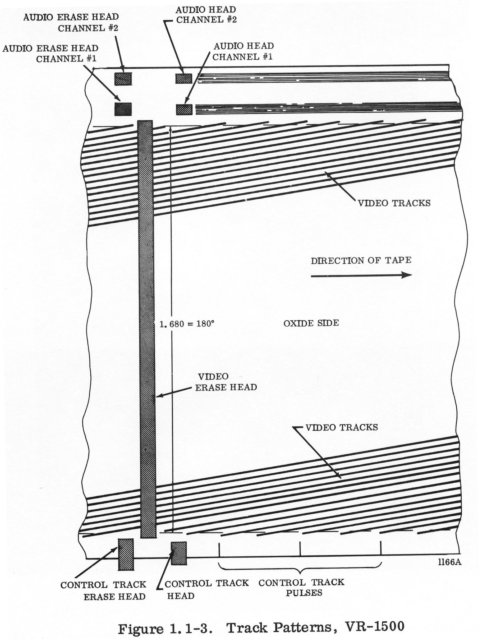

The third and fourth

photos are graphics of the tape threading path on the VR-1500. This tape

path is identical for the VR-660. The fifth photo is a graphic of the pattern

produced on tape by the VR-1500. The VR-660 conforms to this same pattern.

The bottom row

of photos shows the machine as I received it. Grant Newland's tapes are

on it in the first three photos. In the last two photos, I show the VR-660

with the large reels capable of recording up to five hours! The very last

photo gives a clear view of the tape ascending around the head drum. That

large roll of tape is very heavy. It weighs about 25 pounds! Thanks to

John Pommon, of [Antique Video Transfer

Service] in San Francisco, for the greatest deal on the large reel

of tape and the empty take up reel.

This machine uses

tape that is two inches wide, running at 3.7 inches per second, wrapped

half way around a two head scanner. It supports two independent audio channels

with audio overdub available on one channel. The video bandwidth is approximately

3 Mhz with a signal to noise ratio of 40 db. Great for monochrome, a little

bit short for color. A later version of this machine, the VR-660C, was

color capable with an external color adapter unit.

Last, but not least,

the VR-660 is 14. 5 inches high X 30 inches wide X 17. 5 inches deep and

weighs 100 pounds (45 Kilos). It was a jewel of miniaturization in its

time if you compare it with the mighty Quadruplex!

UPDATE: The missing tape guides are being remanufactured for me

from critical dimensions provided to me by John Turner of [Turner

Engineering Inc.] in New Jersey. Thanks John!

For a giggle, [CLICK

HERE] to see the VR-660s baby! I guess the unit was pregnant when I

got it?

NEEDED: Operator and Service Manuals for the VR-660. Will trade

for a copy of the VR-1500 manual. |

Progress Report: 020618

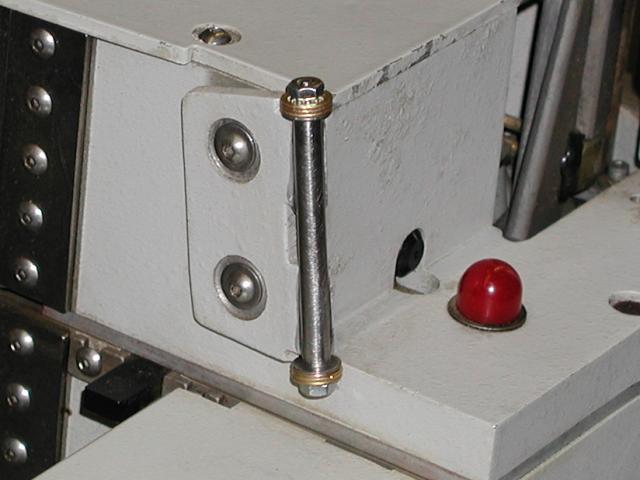

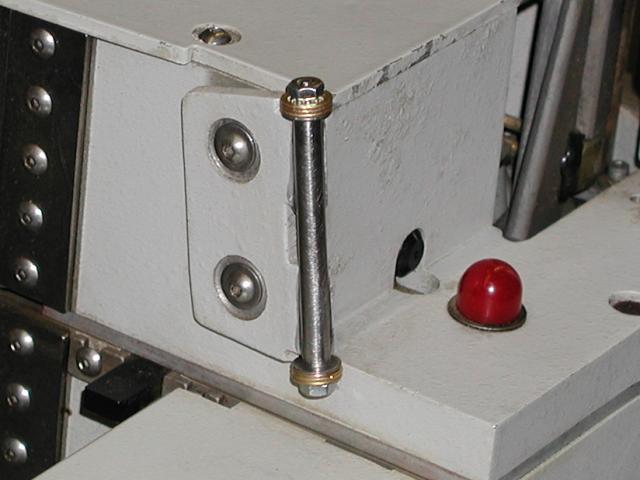

RESTORATION REPORT #1: The VR-660 gets new entrance

and exit guide pins!

With

information provided by John Turner, I have managed to get replacement

tape guide pins manufactured for my Ampex VR-660.

What exactly are entrance

and exit guides, LabGuy? I'm glad you asked! These two guides are the

most important points in the tape path on any video tape recorder. These

two guides are responsible for precisely changing the tape direction so

that it follows an absolutely precise path around the head drum. The first

part of that function is to change the tape travel from a level direction,

parallel with the top plane of the transport, to an angled rise (in this

case) taking the tape around the drum in a spiral or helix. Hence

the term, helical scan! The scan part is not helical only the travel of

the tape around the drum. The exit guide performs the reverse translation

as the entrance guide, returning tape travel to its original horizontal

plane.

While the tape is circumscribing

the drum, it must also be positioned so that the prerecorded video tracks

are lying in a perfectly horizontal plane with the video heads. The heads

protrude from a slot around the drum and contact the tape. As the head

disk spins, inside the drum, the heads trace perfectly horizontal bands

across the tape. When the tape is not wrapped around the drum, these tracks

are actually at an angle, relative to the edge of the tape. But, they should

be perfectly straight. The drum guides are mostly responsible for this

precision geometry. Drum roundness, exact centering of the heads and other

factors are also important in achieving perfect tape geometry. But, these

guides are the most important part to restoring this machine!

Another property of these guides

is their mechanical stability. They need to be precisely shaped and positioned

to do their job correctly. A little too far one way or another and the

tape will not meet the face of the drum correctly. Wrinkling, riding up

or down the drum, edge damage and other geometric horrors can occur. |

The guides must also be very hard since the

oxide recording surface of the tape will be riding over them continuously

in all transport modes. To soft of a metal and the guides would wear out

in a very short time. The guides must also be non magnetic so that the

tape is not partially or, in extreme cases, completely erased by passing

over them! These guides are made from precisely machined stainless steel

for this job.

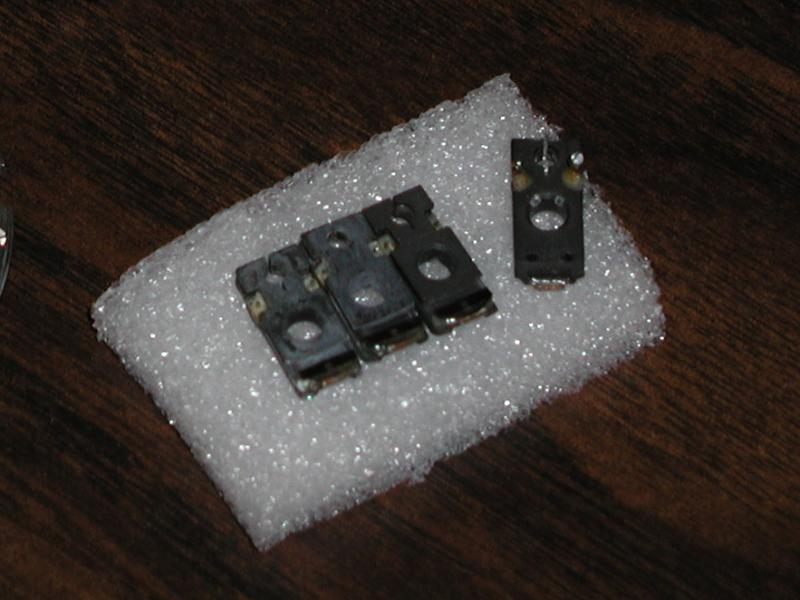

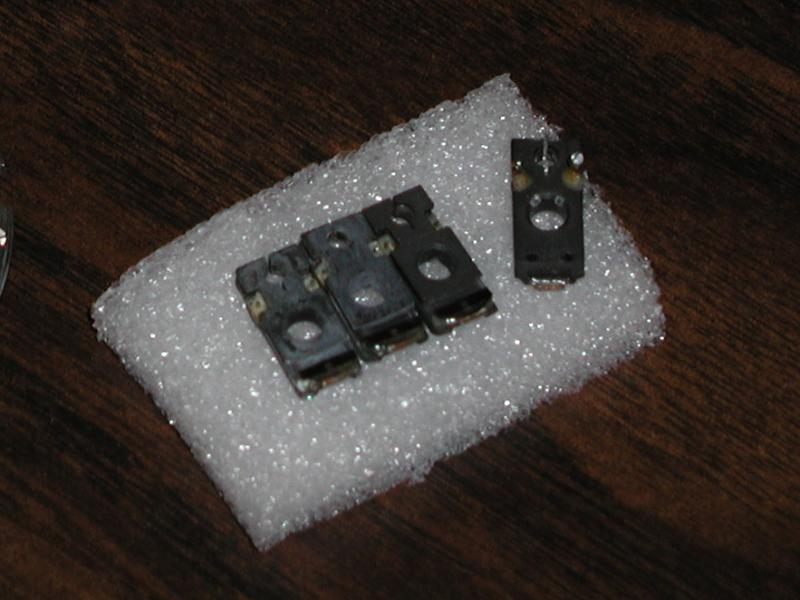

In the first photo, LabGuy

is cleaning the aluminum support bracket for the entrance guide which is

on the bottom. I had to scrape out the old epoxy and clean the metal surface,

removing all dirt and oil that my have been there. I used an industrial

non CFC solvent similar to freon for this part of the job. The upper guide

support got exactly the same treatment. Next, the guide pins were assembled

and cleaned with solvent. The prep work took most of my lunch hour. As

a last step, I mixed up some two part epoxy and secured the pins to the

guides. A couple industrial paper clips held the pins tightly while the

glue set.

After a couple of hours, the

clips were removed to reveal perfectly installed tape guides! As can be

seen in photos two and three. Barely containing my excitement, I tossed

a reel of tape onto the deck and threaded it up. To my amazement, I was

able to rotate the take reel with two fingers, even though there are many

square inches of tape in continuous contact with the fixed surface of the

drum! The resistance of the tape, to this static surface, is called stiction.

The last two photos clearly show the tape travel around the guides and

head drum. No wrinkles, no creases, no folded edges. It is perfectly good

to continue to the next phase, transport restoration!

LabGuy's World would like to

thank Charley at [ACI Alloys] for

accepting the contract to make these parts. Without your help, this project

would be progressing at a much slower rate! Thanks Charley!

Stay tuned! |

Progress Report: 020913:

RESTORATION REPORT #2: Will Quadruplex VTR heads

work in a VR-660?

| That

is the big question, huh? I recently obtained an old Ampex quadruplex VTR

head assembly. Working very carefully, as to not damage the actual video

head tips, I disassembled the unit. In the first photo, you ca see what

was left after my salvage operation. To the left is the main motor assembly,

covered in red iron oxide powder that accumulated under the main covers.

Lower right is the remains of the head wheel. To the right of that is the

four video head "tips", as I call them. |

The second

photo is a close up of the individual head tips. Soon as I get a chance,

I will try them in the VR-660. My reasoning is that if Ampex engineers

were designing a whole VTR from scratch, but the company was already fabricating

a large quantity of high quality tape heads, why not use them in the new

design? It is good logic, but nothing guarantees it is correct.

Stay tuned! |

NEW! 02.01.01

Updated Info! 02.03.18

IVC 9000 Two Inch Helical Video Tape Recorder!

SOLD

This VTR has has two heads and a scanning speed of 1500 inches per second.

The tape is two inches wide, and at 8 inches per second a 4800 foot spool

gives two hours of program time. The machine measures 49" x 28" x 62" and

has the reels at waist height for easy loading and the monitors at eye

level. All edit modes are provided through its built in electronic editor.

The head drum is smaller

than in other IVC helical machines, with only a 5-1/4" wrap of tape. The

picture is divided into 54 line segments compared to the 16 line segment

of a quad machine. This gives a high quality picture which has sufficient

time base stability for broadcasting.

A completely new track lay

out had been devised. The cue track is an audio track of lesser quality

than the main audio tracks. The control track has been moved inboard from

the edge of the tape for protection, and a new track had been added

outside this for SMPTE or other edit codes. All of these tracks can be

erased and recorded separately from each other, and none of them interfered

with the video.

Several new mechanical

features had been included. The motor mounting board is made of a special

"waffle" construction to give added rigidity to the transport. The tape

tension is kept constant by vacuum columns for tape loops, and servo controlled

reel motors, with optical sensors on the tape loops. The system can control

tension even in rewind and fast forward, which was one of the problems

of the quad head machines. This transport system allows the use of nonmetallic

capstan, which can drive the tape without a pressure roller.

Hot pressed ferrite heads

with a 1500 hour life span are used. These have a frequency response to

18 Mhz, which permits FM frequencies of 9 to 12 Mhz to be used. This is

ideal for PAL and SECAM, which use higher frequencies than the NTSC

color system. The short tracks allow smooth switching and good RF recovery

from the tape.

Electronically, the time

base errors can be corrected to +/- 1. 6 nS. The machine can be advanced

or retarded by 64 microseconds, about one horizontal line, in steps of

127 nS. This is controlled by a 7.875 Mhz master oscillator which also

acts as the reference for all the servos. This frequency is chosen because

it is an exact multiple of the horizontal frequencies in both the 525 and

625 line systems.

The head outputs are

compared during the burst time and are set to be equal, thus preventing

banding in the playback mode. After head switching, a chroma to luminance

ratio is set, either manually or automatically.

[CLICK HERE] to read four technical

papers about the IVC-9000. |

Since the time base errors are effected by the drum velocity, tape velocity,

and tape tension, a total of four servos are used. These are the head drum

servo, capstan servo, tension servo, and reel servo. All are very tightly

controlled and are much more complicated than those usually found in VTRs.

The head drum is driven by an unusual DC motor which has a high resolution

optical disc attached to it for servo feedback control. The disc has 40

lines scored on it, and at the proper rate of rotation, it produces a 6

Khz signal. The capstan motor is a permanent magnet DC motor, which has

a similar disc with 1500 lines.

These are getting rare. Unofficially,

only about 35 machines were ever built. When I got this one, two others

went to the land fill. From asking around, I estimate that over half of

all of the 9000s ever made are now history. Originally selling for over

$220,000 a piece in the early 1980's, I got this one for only $200 in 2001.

As usual, "It was working when it was last used". Yeah, like in 1989! This

poor thing sat in a dusty warehouse for almost 10 years before being rescued

from oblivion by yours truly. The dirt is very thick on this old fella.

It will take a lot of TLC to get it running. Stay tuned as the cleaning

and restoration continues!

This is VTR #1 from a

company called The Post Group, formerly located in Los Angeles. I guess

they are no longer in business. Some of you folks, out there, may have

edited your TV programs on this very machine! If so, please write

and share your anecdotes with the other readers of this page.

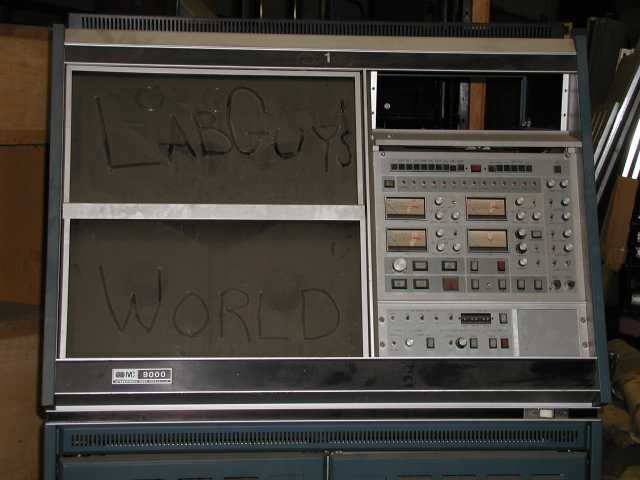

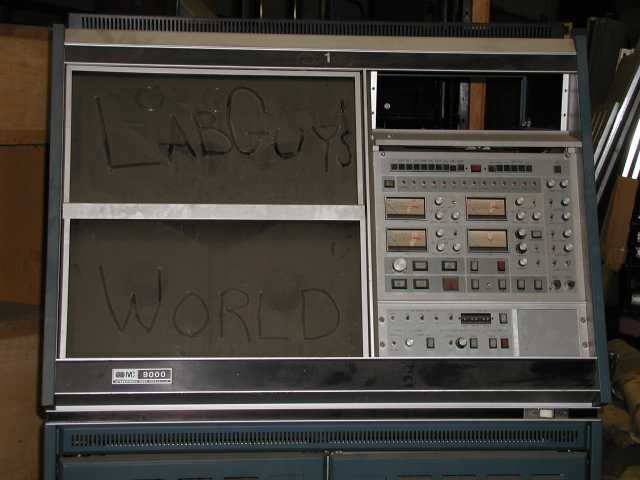

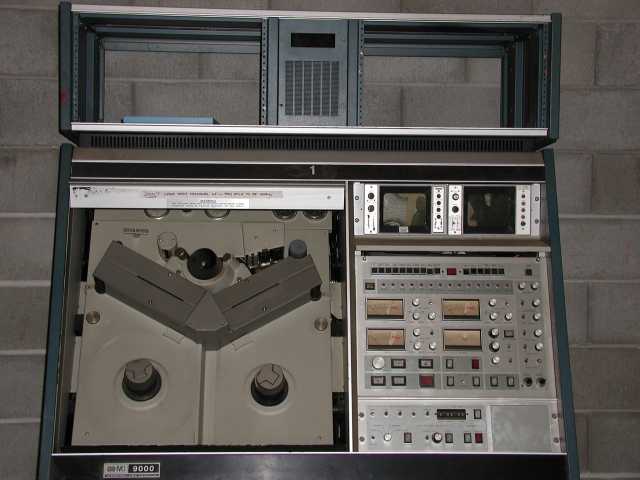

The first photo shows

the machine as I found it, still sitting in the warehouse in Los Angeles.

I thought the touch of whimsy was totally appropriate, since just hiking

through the building to get to the VTR had gotten me as dirty as the rest

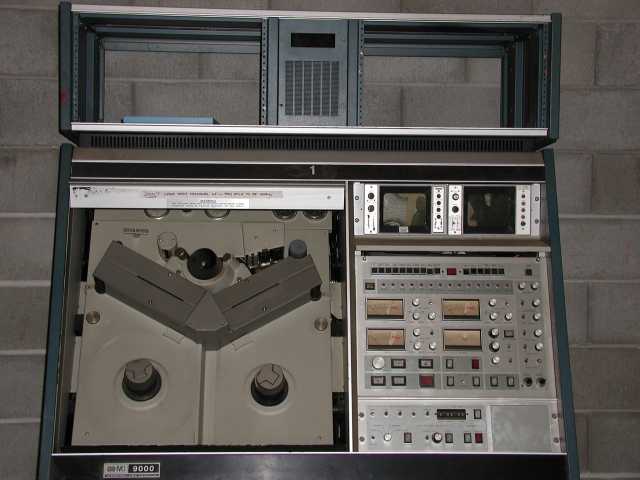

of the place! The second photo shows the deck covers open, revealing the

myriad of complex tape threading paths and electronics controls. The third

photo shows the electronics cage and, below that, the DC power supplies.

The fourth photo is a nice close look at the deck. The V shaped assembly

below the head drum is the vacuum tension columns where the tape was pulled

into during operation. This system is one of the most complex transports

ever built. It is really a "helical-ized" quad machine. Think Ampex, look

familiar?

I have all of the manuals

and the complete machine. It still requires an external supply of dry compressed

air and 220 volt service. If you have any parts, info, tapes, etc., that

you would like rescued from the well of time, just drop me a line and I

am always enthusiastic to help! The rubber rollers have attained a lovely

liquid consistency resembling road tar. Spare parts might be a groove too! |

Click here to:

Go

to the Next Exhibit: One Inch Format VTR's

Return

to the Exhibit Index

Return

to The Top of LabGuy's World

Last updated: March 15, 2004 |