This VTR has has two heads and a scanning speed of 1500 inches per second.

The tape is two inches wide, and at 8 inches per second a 4800 foot spool

gives two hours of program time. The machine measures 49" x 28" x 62" and

has the reels at waist height for easy loading and the monitors at eye

level. All edit modes are provided through its built in electronic editor.

The head

drum is smaller than in other IVC helical machines, with only a 5-1/4"

wrap of tape. The picture is divided into 54 line segments compared to

the 16 line segment of a quad machine. This gives a high quality picture

which has sufficient time base stability for broadcasting.

A completely

new track lay out had been devised. The cue track is an audio track of

lesser quality than the main audio tracks. The control track has been moved

inboard from the edge of the tape for protection, and a new track had been

added outside this for SMPTE or other edit codes. All of these tracks

can be erased and recorded separately from each other, and none of them

interfered with the video.

Several

new mechanical features had been included. The motor mounting board is

made of a special "waffle" construction to give added rigidity to the transport.

The tape tension is kept constant by vacuum columns for tape loops, and

servo controlled reel motors, with optical sensors on the tape loops. The

system can control tension even in rewind and fast forward, which was one

of the problems of the quad head machines. This transport system allows

the use of nonmetallic capstan, which can drive the tape without a pressure

roller.

Hot pressed

ferrite heads with a 1500 hour life span are used. These have a frequency

response to 18 Mhz, which permits FM frequencies of 9 to 12 Mhz to be used.

This is ideal for PAL and SECAM, which use higher frequencies than

the NTSC color system. The short tracks allow smooth switching and good

RF recovery from the tape.

Electronically,

the time base errors can be corrected to +/- 1. 6 nS. The machine can be

advanced or retarded by 64 microseconds, about one horizontal line, in

steps of 127 nS. This is controlled by a 7.875 Mhz master oscillator which

also acts as the reference for all the servos. This frequency is chosen

because it is an exact multiple of the horizontal frequencies in both the

525 and 625 line systems.

The head

outputs are compared during the burst time and are set to be equal, thus

preventing banding in the playback mode. After head switching, a chroma

to luminance ratio is set, either manually or automatically.

[CLICK HERE] to

read four technical papers about the IVC-9000. |

Since the time base errors are effected by the drum velocity, tape velocity,

and tape tension, a total of four servos are used. These are the head drum

servo, capstan servo, tension servo, and reel servo. All are very tightly

controlled and are much more complicated than those usually found in VTRs.

The head drum is driven by an unusual DC motor which has a high resolution

optical disc attached to it for servo feedback control. The disc has 40

lines scored on it, and at the proper rate of rotation, it produces a 6

Khz signal. The capstan motor is a permanent magnet DC motor, which has

a similar disc with 1500 lines.

These are getting

rare. Unofficially, only about 35 machines were ever built. When I got

this one, two others went to the land fill. From asking around, I estimate

that over half of all of the 9000s ever made are now history. Originally

selling for over $220,000 a piece in the early 1980's, I got this one for

only $200 in 2001. As usual, "It was working when it was last used". Yeah,

like in 1989! This poor thing sat in a dusty warehouse for almost 10 years

before being rescued from oblivion by yours truly. The dirt is very thick

on this old fella. It will take a lot of TLC to get it running. Stay tuned

as the cleaning and restoration continues!

This is

VTR #1 from a company called The Post Group, formerly located in Los Angeles.

I guess they are no longer in business. Some of you folks, out there, may

have edited your TV programs on this very machine! If so, please

write and share your anecdotes with the other readers of this page.

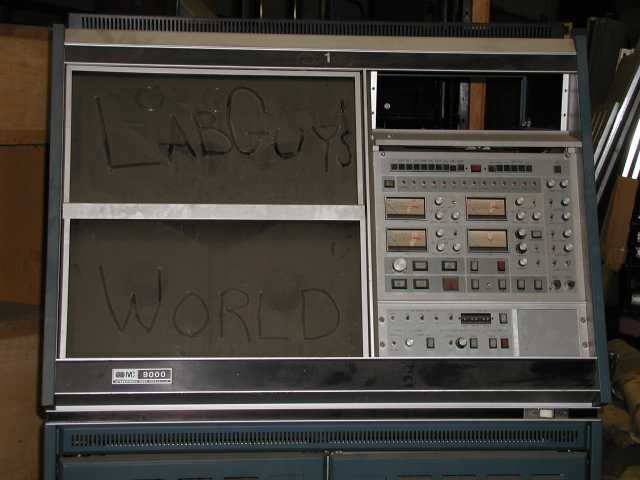

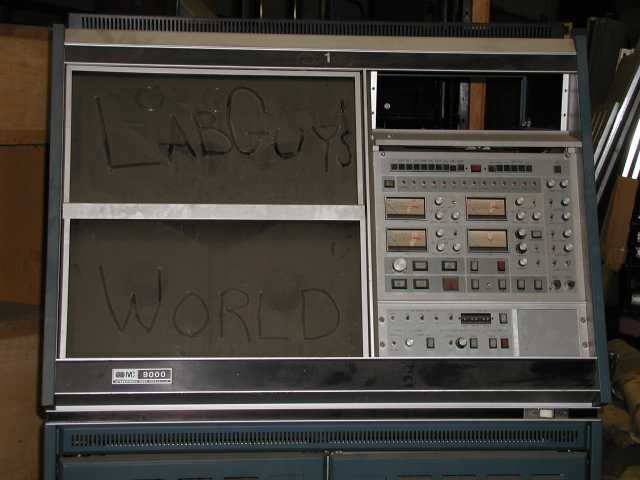

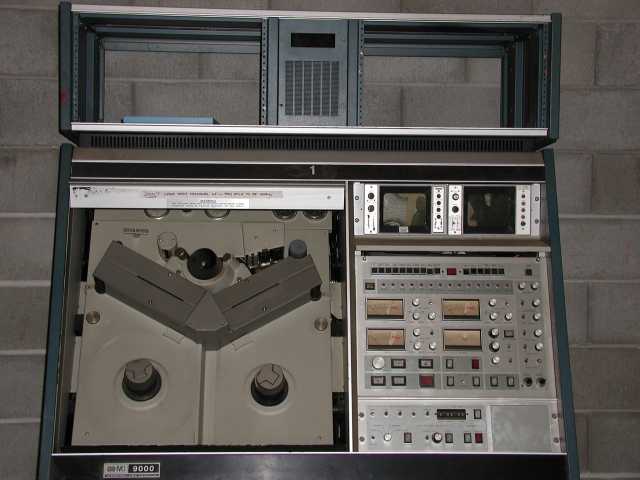

The first

photo shows the machine as I found it, still sitting in the warehouse in

Los Angeles. I thought the touch of whimsy was totally appropriate, since

just hiking through the building to get to the VTR had gotten me as dirty

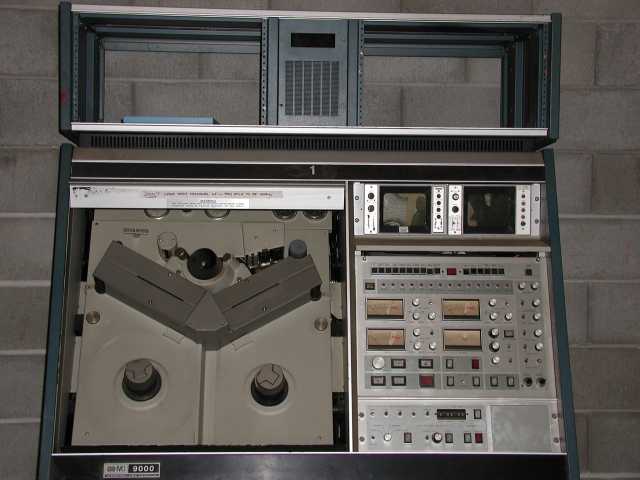

as the rest of the place! The second photo shows the deck covers open,

revealing the myriad of complex tape threading paths and electronics controls.

The third photo shows the electronics cage and, below that, the DC power

supplies. The fourth photo is a nice close look at the deck. The V shaped

assembly below the head drum is the vacuum tension columns where the tape

was pulled into during operation. This system is one of the most complex

transports ever built. It is really a "helical-ized" quad machine. Think

Ampex, look familiar?

I have

all of the manuals and the complete machine. It still requires an external

supply of dry compressed air and 220 volt service. If you have any parts,

info, tapes, etc., that you would like rescued from the well of time, just

drop me a line and I am always enthusiastic to help! The rubber rollers

have attained a lovely liquid consistency resembling road tar. Spare parts

might be a groove too! |